Introduction to Mega LED Profile Company

Founded in the early 2000s, Mega LED Profile Company has established itself as a leading manufacturer of silicone profiles designed specifically for LED lights. With a commitment to innovation and quality, the company has consistently driven advancements in the field, providing a diverse range of products tailored to meet the evolving needs of its clients. Over the years, Mega LED Profile has expanded its operations beyond its initial offerings, showcasing its technical prowess and dedication to the development of high-performance silicone solutions.

The company’s vision centers on harnessing the benefits of silicone materials to enhance LED lighting applications. By focusing on durability, flexibility, and efficient light diffusion, Mega LED Profile aims to provide cutting-edge products that cater to both commercial and residential lighting solutions. This strategic approach has earned the company a prominent market presence, allowing it to serve a wide array of industries including architecture, interior design, and manufacturing.

Recognized for its superior quality and innovative design, Mega LED Profile Company has garnered numerous accolades and certifications, validating its position as a trusted name in the industry. The company leverages advanced manufacturing technologies and processes that ensure precision and consistency across its product lines. By maintaining strict quality control measures, Mega LED Profile guarantees that each silicone profile meets the highest industry standards.

As the demand for energy-efficient lighting solutions continues to grow, so does Mega LED Profile’s commitment to sustainability and environmental stewardship. With a focus on eco-friendly practices, the company actively participates in initiatives aimed at promoting green building standards and reducing overall carbon footprint. In doing so, Mega LED Profile not only enhances its reputation but also contributes to a more sustainable future within the lighting industry.

Advantages of Silicone Profiles

Silicone profiles have emerged as a popular choice in LED lighting applications due to their numerous advantages over traditional materials. One of the most significant benefits is their excellent corrosion resistance. Silicone exhibits remarkable resistance to harsh environmental factors, making it a durable option for various conditions. This characteristic ensures that silicone profiles maintain their integrity and performance over time, even when exposed to moisture, UV rays, or extreme temperatures.

Another key advantage of silicone profiles is their impressive light transmittance. Unlike other materials that may diffuse or obstruct the flow of light, silicone allows for optimal light passage, ensuring better illumination in LED lighting setups. This quality enhances the overall aesthetic and functional aspects of lighting, making silicone an ideal choice for both commercial and residential applications.

Moreover, the flexibility of silicone profiles is a notable benefit. Their capacity to be molded into different shapes and sizes makes them adaptable for various designs. This flexibility not only simplifies installation but also allows for creative lighting solutions that meet diverse architectural needs.

Thermal conductivity is also a crucial aspect of silicone profiles in LED lighting. Silicone effectively disperses heat away from LED lights, ensuring that temperature rises are minimized, therefore extending the lifespan of the lighting fixtures. This natural heat management contributes to better performance and reduced energy consumption.

Temperature range stability is yet another advantage. Silicone profiles can withstand a wide range of temperatures without losing their physical properties. This stability is vital in maintaining consistent performance in environments with fluctuating temperatures.

Finally, environmental safety is a compelling reason for opting for silicone profiles. Silicone is non-toxic and does not release harmful substances, making it a sustainable choice that aligns with modern environmental standards. These attributes collectively underscore why silicone profiles are increasingly favored in LED lighting applications over traditional materials.

Corrosion Resistance: Ensuring Longevity

Corrosion resistance is a critical characteristic of silicone profiles, notably for applications involving LED lighting. These profiles are engineered to withstand the potentially damaging effects of ordinary acids, alkalis, and salts, making them an ideal choice for various environments. The materials utilized in the manufacturing of silicone profiles boast a high resistance to chemical degradation, which is fundamental to enhancing the longevity and performance of LED lights.

In particular, silicone profiles can be beneficial in coastal areas, where exposure to saltwater can lead to rapid corrosion of less resistant materials. In such applications, silicone profiles provide a protective barrier that safeguards LED components from rust and deterioration, ensuring that illumination remains consistent and reliable. Additionally, environments within industrial sectors, where exposure to various chemical substances is prevalent, further necessitate the use of silicone in LED lighting applications assured of its resilience against corrosive elements.

Furthermore, silicone’s inherent flexibility is contributing to its superiority in terms of durability. This flexibility allows it to adapt to temperature fluctuations and physical stresses while maintaining its integrity and resistance properties. Unlike traditional materials, silicone profiles do not become brittle or chip over time, even under adverse conditions. This quality is particularly important in outdoor LED lighting applications, where temperature variations and moisture can exacerbate material degradation. By using silicone profiles, manufacturers can ensure that the longevity of their LED lighting systems is not compromised by environmental factors.

Ultimately, the corrosion resistance of silicone profiles stands as a fundamental aspect of their design that extends the operational lifespan of LED products. By integrating this exceptional quality into LED lighting solutions, manufacturers can offer products that are not only efficient but also durable and reliable, even in the most challenging conditions.

Light Transmittance: Enhancing Brightness

Light transmittance is a critical factor in the performance of LED profiles, particularly those made from silicone. This property determines the amount of light that passes through the material, ultimately influencing the brightness and efficiency of the lighting system. Notably, silicone profiles exhibit impressive transmittance levels exceeding 80%, which plays a significant role in optimizing the output of LED lights.

High light transmittance contributes directly to the effectiveness of LED lighting systems. With silicone profiles allowing more light to pass through, there is less light loss during the process of illumination. This efficiency not only boosts the overall brightness of LED fixtures but also enhances their energy efficiency. In commercial and residential settings, adequately lit environments are essential for functionality and aesthetics. By utilizing silicone profiles with high transmittance, manufacturers can create LED lighting solutions that cater to varying applications, from simple task lighting to complex architectural installations.

Furthermore, the benefits of using silicone in LED profiles extend beyond mere light output. Silicone materials offer superior durability, flexibility, and resistance to environmental factors such as heat and moisture. This versatility makes silicone profiles an ideal option for both indoor and outdoor lighting solutions. The ability to maintain high transmittance without compromising on durability is crucial for achieving long-lasting LED installations.

Additionally, silicone’s inherent properties contribute to a uniform light distribution, minimizing hotspots and providing a consistent illumination level across surfaces. Enhanced brightness and uniformity are vital for applications where precision lighting is required, such as in retail displays, museums, and galleries. By selecting silicone LED profiles with high light transmittance, designers and manufacturers ensure that their products meet the demands of modern lighting applications efficiently.

Thermal Conductivity: Managing Heat

One of the key advantages of silicone profiles over traditional PVC materials is their superior thermal conductivity. This characteristic plays a crucial role in the performance and longevity of LED lights. In an era where energy efficiency and durability are paramount, the choice of material can significantly impact the overall functionality of lighting products.

Silicone profiles excel in their ability to dissipate heat efficiently. When an LED light operates, it generates heat as a byproduct of converting electrical energy into light. Effective heat management is critical, as excessive heat can reduce the efficiency of the light source and contribute to premature failure. By utilizing silicone profiles, manufacturers ensure that heat is conducted away from the LED components more effectively than with PVC options, thereby mitigating the risk of overheating.

The natural properties of silicone enable it to withstand higher temperatures without compromising its structural integrity. This thermal resilience means that silicone profiles maintain their shape and efficiency over longer periods of use, which is particularly beneficial in applications requiring consistent brightness, such as architectural lighting and outdoor fixtures. The enhanced heat dissipation not only boosts the performance of the LEDs but also extends their operational lifespan, ultimately providing a more reliable lighting solution.

In addition, silicone’s low thermal resistance is paramount in preserving the lumens emitted by LEDs, ensuring that the light produced remains bright and consistent. By managing heat effectively, silicone profiles contribute to the overall energy savings of LED systems. As the demand for high-quality LED lighting solutions continues to grow, the advantages of silicone profiles in thermal management become increasingly valuable, solidifying their position as a preferred choice in the industry. Thus, understanding the integral role of thermal conductivity in silicone profiles illuminates their significance in advancing LED technology.

Versatility: Softness and Shapeability

Silicone profiles are renowned for their remarkable softness and shapeability, making them a preferred choice for various applications, particularly within the realm of LED lighting solutions. The intrinsic properties of silicone allow it to be manipulated into a multitude of forms, catering to the specific requirements of designers and manufacturers alike. This versatility is particularly advantageous for creative endeavors, ranging from custom LED installations to unique advertising displays such as billboards.

The flexibility of silicone profiles enables easy integration into diverse lighting projects. Whether it’s curving around corners or conforming to non-standard shapes, silicone materials adapt seamlessly. This adaptability enhances the creative freedom for designers, allowing them to explore unconventional layouts and innovative configurations. For instance, when used in LED solutions, the ability to shape silicone profiles ensures that light can be directed precisely where it is needed, maximizing illumination while minimizing waste.

Moreover, the softness of silicone profiles contributes to their ease of handling during installation. Unlike rigid materials, these profiles can be manipulated without special tools, reducing labor time and costs associated with project execution. This factor is particularly crucial for large-scale projects, where efficiency is paramount. The soft texture also makes silicone profiles suitable for public displays, as they are less likely to cause injury or damage during interactions.

Ultimately, the merging of softness and shapeability in silicone profiles underscores their practical and aesthetic benefits. This versatility not only meets the evolving needs of the market but also inspires innovation in lighting design, allowing for a myriad of applications that spotlight the capabilities of this unique material. As a leader in manufacturing silicone profiles for LED lights, Mega LED Profile Company continues to push the boundaries of what is achievable in creative project implementations.

Environmental Safety: Meeting Standards

The use of silicone profiles in the manufacturing of LED lights has emerged as a leading solution for various environmental safety considerations. One of the primary advantages of these silicone profiles is their food-grade safety, ensuring that they meet stringent health and safety regulations. This quality makes silicone profiles suitable for use in environments where contact with food items is a concern, as they are free from harmful chemicals and toxins that could potentially leach into consumables.

Additionally, silicone profiles exhibit remarkable waterproofing capabilities. This characteristic is essential for applications exposed to moisture, ensuring that the lighting solutions maintain their integrity and functionality in wet environments, such as kitchens or outdoor settings. The water-resistant properties of silicone enhance the durability of LED lighting solutions, extending their lifespan and reliability without the risk of electrical failures associated with the ingress of water.

Fire-resistance is another critical aspect of silicone profiles that contributes to their safety. These profiles can withstand high temperatures without melting or emitting toxic fumes, making them an excellent option for installations in areas prone to heat exposure. This property not only enhances the safety of LED lights but also meets the stringent fire safety standards required in numerous industrial and residential applications.

Moreover, silicone’s anti-tear properties further elevate its desirability as a material for LED lighting solutions. The resilience against tearing ensures that the profiles remain intact under stress during installation and usage. This robustness not only guarantees the performance of the LED lights but also maintains safety across various applications requiring rigorous adherence to safety standards.

In terms of versatility, silicone profiles can be employed in a multitude of applications, catering to specific demands that necessitate adherence to higher safety benchmarks, promoting a sustainable and secure environment.

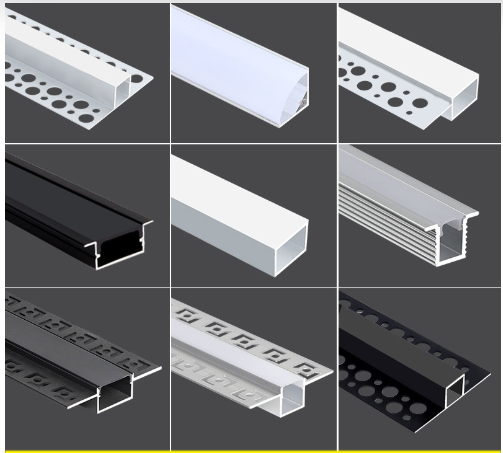

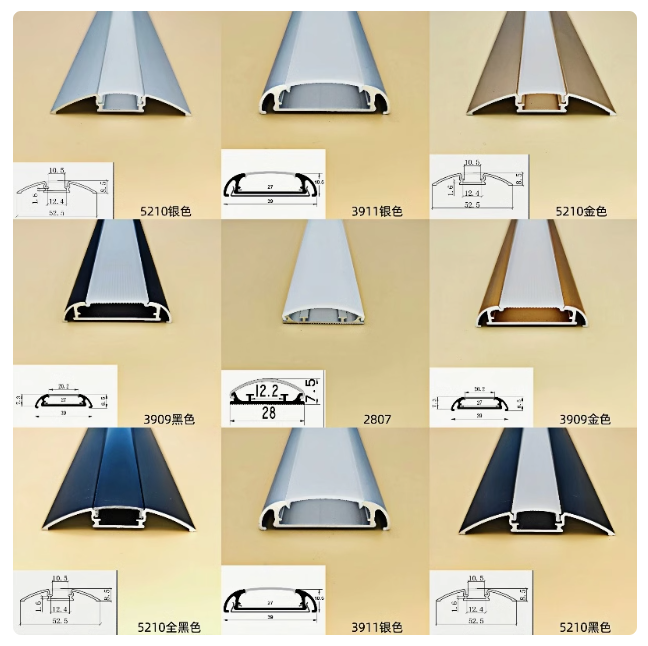

Product Range: Exploring Mega’s Offerings

Mega LED Profile Company stands out as a prominent player in the manufacturing of silicone profiles for LED lights, offering a diverse and comprehensive product range designed to meet various lighting needs. Within their extensive catalog, customers will find an array of profiles tailored for different applications, including side view, front side view, and three-side view profiles, among others.

The side view profiles are engineered to provide optimal light diffusion and create a seamless glow, making them ideal for installations where a sleek appearance is desired. These profiles are particularly well-suited for use in residential and commercial settings, allowing users to customize their lighting solutions effectively. With variations in dimensions and finishes, Mega ensures that there is a side view profile for every project requirement.

For applications requiring direct illumination from the front, the front side view profiles offer a specialized design that enhances light output while maintaining a refined aesthetic. These profiles are especially beneficial in environments such as retail spaces and showcases, where bright, focused lighting is crucial to highlight products or artworks. Mega’s commitment to quality ensures that their front side view profiles are not only functional but also durable and visually appealing.

Additionally, Mega LED Profile Company provides three-side view profiles, which allow for versatile lighting arrangements. These profiles enable light to emit from three sides, making them an excellent choice for corner installations or areas where ambient lighting is needed from multiple angles. The innovation behind these profiles reflects the company’s dedication to providing flexible solutions that cater to diverse architectural and design requirements.

Overall, Mega LED Profile Company’s product range exemplifies their expertise in silicone profiles, ensuring clients have access to high-quality options that enhance both functionality and design in LED lighting applications.

Engineering Expertise: The Backbone of Quality

The engineering team at Mega LED Profile Company represents the cornerstone of its operational success and product quality. With a dedicated workforce composed of over 20 qualified engineers, they bring a wealth of knowledge and experience to the design and manufacturing of silicone profiles for LED lights. The team’s depth of expertise ensures that every product meets the rigorous standards set by the industry, a commitment that has significantly contributed to Mega’s reputation as a leading manufacturer in the field.

Each member of the engineering team possesses specialized skills and extensive training, which are essential in navigating the complex requirements of LED profile production. From conceptualizing innovative designs to fine-tuning the manufacturing processes, their comprehensive understanding of materials science and engineering principles underpins the quality of silicone profiles. This expertise is not merely theoretical; it is a practical application that results in products that are both functional and aesthetically pleasing.

Over the past 12 years, Mega LED Profile Company has successfully exported its high-quality products to 66 countries, a testament to the team’s dedication to excellence. The engineers work collaboratively on various projects, utilizing advanced technology and industry best practices to ensure that every LED profile adheres to both performance and safety standards. Their focus on continuous improvement and innovation allows Mega to adapt to changing market demands, ultimately leading to enhanced product offerings that meet diverse customer needs.

By fostering an environment of teamwork and ongoing professional development, the engineering team at Mega LED Profile Company remains at the forefront of the industry. This commitment not only reinforces the company’s reputation but also propels it toward future advancements in LED lighting solutions, solidifying its position as a trusted partner for clients worldwide.

Conclusion: A Leader in LED Solutions

In the realm of LED solutions, Mega LED Profile Company has established itself as a preeminent manufacturer of silicone profiles. With a steadfast commitment to quality, innovation, and customer satisfaction, the company consistently delivers products that not only meet but exceed industry standards. Their silicone profiles are engineered to optimize LED performance, ensuring durability and longevity while enhancing aesthetic appeal.

One of the key strengths of Mega LED Profile Company lies in its unwavering focus on technological advancement. By leveraging the latest advancements in material science, the company has developed silicone profiles that offer superior flexibility and resistance to environmental factors, making them suitable for a wide range of applications. Furthermore, their research and development efforts have facilitated the creation of custom solutions tailored to specific project requirements, showcasing their adaptability in a competitive market.

Customer satisfaction is at the heart of Mega’s operations. The company prides itself on building strong relationships with clients, ensuring that their needs are understood and addressed throughout the project lifecycle. From initial consultation to post-purchase support, Mega LED Profile Company is dedicated to providing a seamless experience, reinforcing its reputation as a reliable partner in the lighting industry.

As the market continues to evolve towards energy-efficient solutions, Mega LED Profile Company stands ready to lead the way, equipping clients with cutting-edge silicone profiles for LED applications. By choosing Mega, clients not only benefit from high-quality products but also from the expertise of a manufacturer committed to sustainable and innovative lighting solutions. For future projects, considering Mega LED Profile Company for silicone profiles is a strategic choice that promises both efficiency and excellence.

The catalog of our silicon profile for led strip light, from our China factory.

FOR MORE ON OUR LED PROFILES: